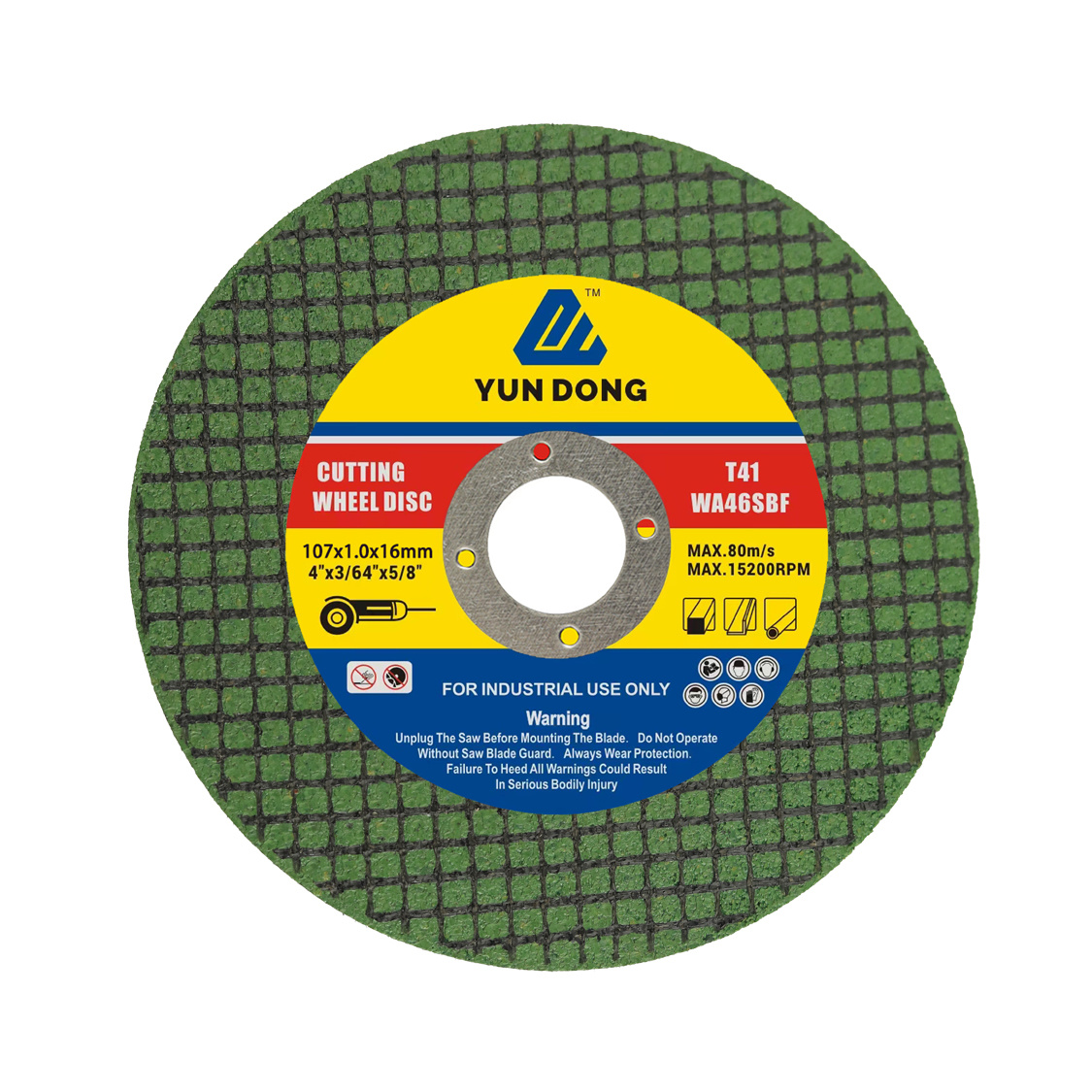

107 Black Dual Mesh

Key words:

Classification:

- Description

Grinding wheel, also known as fixed abrasive, grinding wheel is a fixed abrasive with a certain strength by bonding agent to consolidate ordinary abrasive into a certain shape (mostly circular, with a through hole in the center). It is generally composed of abrasive, bonding agent and pores, which are often referred to as the three elements of fixed abrasive tools. According to the different classification of the binder, the common ones are ceramic (binder) grinding wheel, resin (binder) grinding wheel, rubber (binder) grinding wheel. Grinding wheel is the largest amount of grinding tools, the use of the most widely, when used in high-speed rotation, can be on the metal or non-metal workpiece of the outer circle, inner circle, plane and various types of surface, such as rough grinding, semi-fine grinding and fine grinding and grooving and cutting.

Product Introduction

Grinding wheel is the most important kind of grinding tool in grinding process. The grinding wheel is a porous body made by adding binder to the abrasive, compacts, drying and roasting. Due to the different abrasives, binders and manufacturing processes, the characteristics of grinding wheels vary greatly, so it has an important impact on the quality, productivity and economy of grinding. The characteristics of grinding wheels are mainly determined by factors such as abrasive, particle size, binder, hardness, organization, shape and size.

Product classification

There are many kinds of grinding wheels. According to the abrasive used, it can be divided into ordinary abrasive (corundum and silicon carbide, etc.) grinding wheel and natural abrasive superhard abrasive and (diamond and cubic boron nitride, etc.) grinding wheel. According to the shape, it can be divided into flat grinding wheel, bevel grinding wheel, cylindrical grinding wheel, cup grinding wheel, disc grinding wheel, etc. According to the binder, it can be divided into ceramic grinding wheel, resin grinding wheel, rubber grinding wheel, metal grinding wheel, etc. The characteristic parameters of the grinding wheel are mainly abrasive, particle size, hardness, bonding agent, shape, size and so on. Since the grinding wheel usually works at high speed, a rotary test (to ensure that the grinding wheel will not break at the working speed) and a static balance test (to prevent machine vibration during work) should be carried out before use. After working for a period of time, the grinding wheel should be dressed to restore grinding performance and correct geometry.

Related Products

Product inquiry

Filling in your phone and email information will help us to contact you in a timely manner and solve your problems as soon as possible.

Address: No. 1-6, North Road, 50 m west of the intersection of Industrial Avenue and Pingshun Road, Xiping County, Zhumadian City, Henan Province

Telephone:+8613979353005

View Mobile